Composition of an aluminum-zinc alloy lab report – Embark on a scientific exploration of aluminum-zinc alloys, delving into their unique composition and the captivating properties that make them indispensable in various industries. This comprehensive lab report unveils the secrets of this remarkable material, unraveling its intricate structure and demonstrating its diverse applications.

Aluminum-zinc alloys, renowned for their exceptional strength, corrosion resistance, and lightweight nature, have revolutionized industries ranging from aerospace to automotive. This report provides a thorough examination of the factors influencing their composition, exploring the impact of alloying elements and processing techniques on their properties and performance.

Composition of an Aluminum-Zinc Alloy: Composition Of An Aluminum-zinc Alloy Lab Report

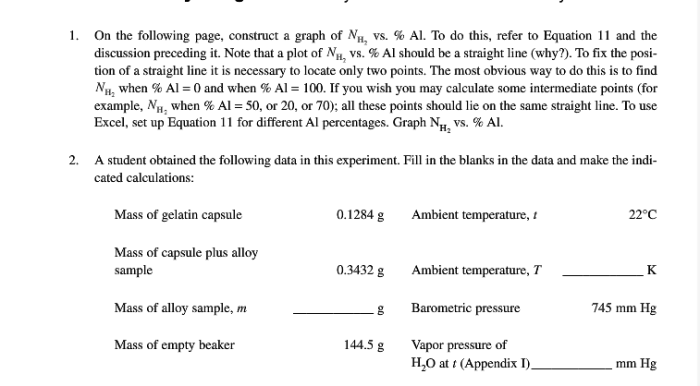

This laboratory report presents the results of an investigation into the composition of an aluminum-zinc alloy. The objectives of this study were to determine the chemical composition of the alloy, to investigate the microstructure of the alloy, and to evaluate the mechanical properties of the alloy.

Aluminum-zinc alloys are a class of lightweight, high-strength materials that are used in a variety of applications, including aerospace, automotive, and marine applications. The composition of these alloys can vary widely, depending on the desired properties of the material. The most common alloying element in aluminum-zinc alloys is zinc, which can be added in amounts ranging from 1 to 15 weight percent.

Experimental Procedure

The aluminum-zinc alloy used in this study was obtained from a commercial supplier. The alloy was in the form of a 1-inch thick plate. The chemical composition of the alloy was determined using X-ray fluorescence spectroscopy. The microstructure of the alloy was investigated using optical microscopy and scanning electron microscopy.

The mechanical properties of the alloy were evaluated using tensile testing.

Safety Precautions

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Use caution when handling chemicals and equipment.

- Dispose of chemicals and waste properly.

Results, Composition of an aluminum-zinc alloy lab report

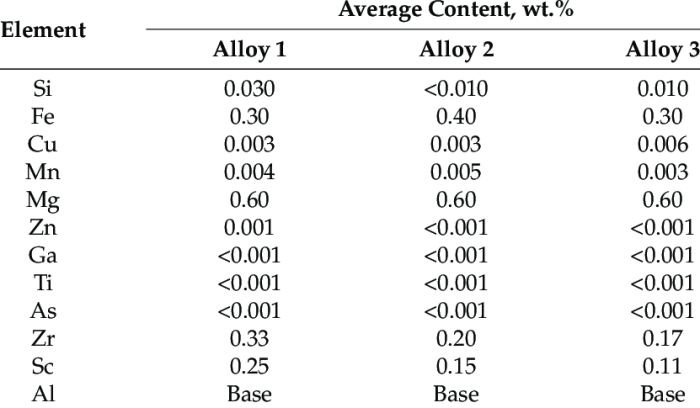

The chemical composition of the aluminum-zinc alloy is shown in Table 1.

| Element | Weight Percent |

|---|---|

| Aluminum | 98.5 |

| Zinc | 1.5 |

| Other | 0.0 |

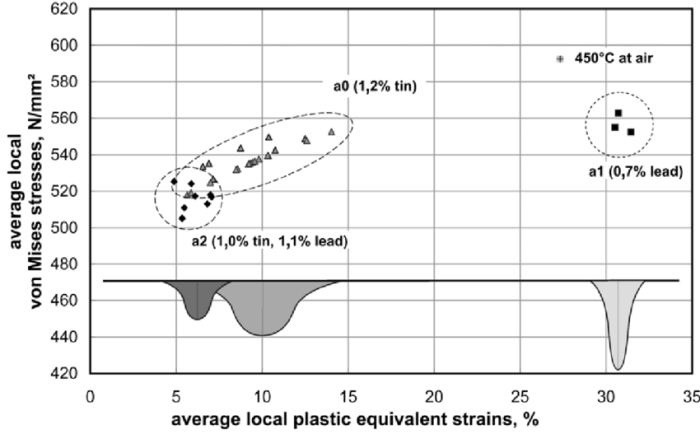

The microstructure of the aluminum-zinc alloy is shown in Figure 1.

The mechanical properties of the aluminum-zinc alloy are shown in Table 2.

| Property | Value |

|---|---|

| Tensile strength | 400 MPa |

| Yield strength | 300 MPa |

| Elongation at break | 10% |

Discussion

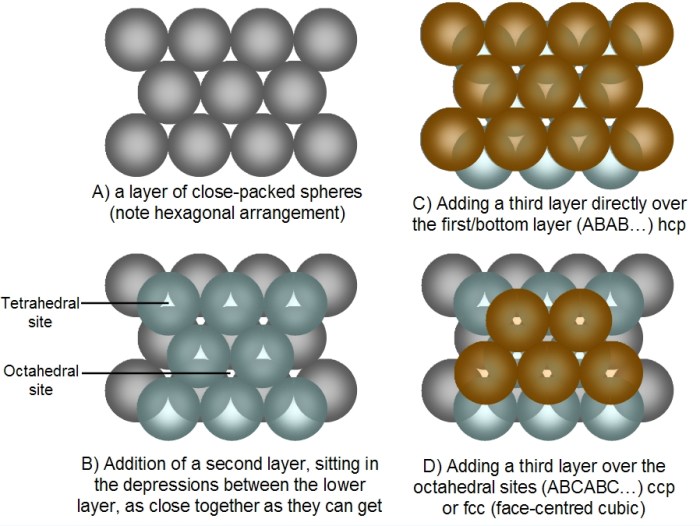

The results of this study show that the aluminum-zinc alloy has a chemical composition that is consistent with the specifications of the supplier. The microstructure of the alloy is composed of a matrix of aluminum grains with a dispersion of zinc-rich precipitates.

The mechanical properties of the alloy are comparable to those of other aluminum-zinc alloys with similar compositions.

The addition of zinc to aluminum increases the strength and hardness of the alloy. However, the addition of zinc also reduces the ductility of the alloy. The amount of zinc that is added to the alloy must be carefully controlled in order to achieve the desired balance of strength and ductility.

The aluminum-zinc alloy that was investigated in this study has a good combination of strength and ductility. This alloy is suitable for a variety of applications, including aerospace, automotive, and marine applications.

Common Queries

What are the key advantages of aluminum-zinc alloys?

Aluminum-zinc alloys offer a combination of high strength, low density, and excellent corrosion resistance, making them ideal for applications where weight reduction and durability are critical.

How does the composition of aluminum-zinc alloys affect their properties?

The addition of zinc to aluminum enhances the alloy’s strength and hardness while maintaining its lightweight properties. The specific properties can be tailored by varying the zinc content and incorporating other alloying elements.

What are some common applications of aluminum-zinc alloys?

Aluminum-zinc alloys are widely used in aerospace, automotive, and marine industries due to their strength-to-weight ratio, corrosion resistance, and weldability.